Advertisment

Revolutionising medication distribution: Oulu University Hospital’s smart unit dose system

Oulu University Hospital in Finland has embarked on an ambitious journey to become “the world’s smartest hospital” and a key part of this transformation is the implementation of a cutting-edge unit dose medicines distribution system. This initiative, spearheaded by Chief Development Pharmacist, Jaakko Mustakallio, promises to reshape medication management processes by making full use of technology to boost productivity and efficiency. In this interview Mr Mustakallio describes the equipment that will be used to pack unit doses, how the day-to-day service will operate and the expected benefits for patients, staff and the hospital.

Currently, medicines are delivered to wards in original packs. Nurses then issue these medicines to individual patients, a process that is both time-consuming and prone to errors. Recognising these limitations, the hospital decided to implement a unit dose supply system to enhance efficiency and patient safety. The main goal of automation is to “liberate time for the nursing staff” allowing them to spend more time with patients and less time in the office or at the medicine cabinet, explains Mr Mustakallio.

Robotic packaging

The unit dose system at Oulu Hospital operates through a two-phase process integrated with the hospital’s patient information system. The workflow begins with electronic prescribing, from which patient medication information flows to the unit dose system.

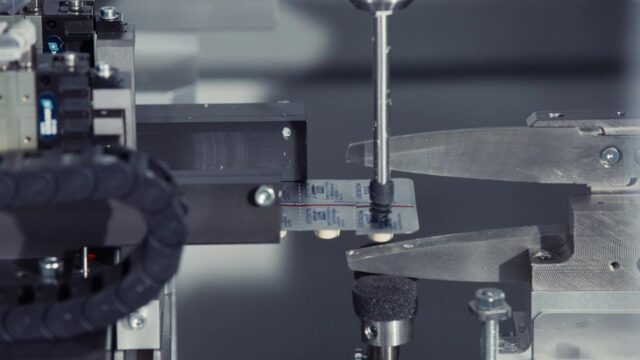

The pharmacy unit dose packaging and storage operation comprises eight Sinteco robots housed in a dedicated,150 square metre, Class D cleanroom where the atmosphere (temperature, air quality and humidity) is carefully controlled. There are additional cleanroom areas for original packs and staff. It is much like a small factory, says Mr Mustakallio. Three Calypso robots repackage medications into individual unit dose pouches. These machines, cleverly named OS (oral solids) and Omnia (all forms), can handle a wide array of medication formats, including ampoules and transdermal patches, he says.

Interior of the Calypso OS robot showing cut blisters of tablets being over-wrapped into unit dose pouches

Blister packs are cut so that the tablets or capsules remain in the blisters, which are then over-wrapped into unit dose pouches.

Interior of the Calypso OS robot showing the original blister pack of tablets being cut

Mr Mustakallio notes that these machines can handle approximately 99% of their medication packaging needs, with only a few exceptions, often due to size or weight limitations, such as some heavy antibiotic preparations.

The completed unit dose pouches, labelled with the name of the medication, batch number and expiry date, are stored in one of the five Pegasus robots, ready to be picked.

Interior of the Pegasus robot showing the stored unit dose pouches ready for picking

Patient-specific medication “rings” or “clips” are automatically assembled by the Pegasus robots in response to prescription data. These clips contain all the medications a patient needs for a particular administration time, complete with a label detailing the patient’s information, ward, administration time, and the list of medications included. The label also includes a QR code that can be scanned at the time of administration to link the prescription, the patient and the medication in a “closed loop”.

Medicines clipped together for a single patient for a specific medicine round, showing biodegradable clip and packaging

Unit dose delivery

Once assembled, these patient-specific therapies are swiftly delivered to the wards via Oulu Hospital’s extensive pneumatic tube system (PTS). The hospital has one of the largest PTS in Europe and has plans to expand further. This system allows for rapid delivery, taking only about five minutes from the pharmacy to any point in the hospital, explains Mr Mustakallio. This just-in-time delivery model minimises the need for extensive medication storage on the wards. Medications are typically delivered approximately one hour before the scheduled administration time, allowing nurses to perform double checks before administration of the doses.

For “as required” doses or emergency medications, the wards will maintain a small stock in automated dispensing cabinets (ADCs) or standard medicine cabinets. These cabinets are also integrated with software for stock control, managed by the pharmacy. A dedicated logistics team in the pharmacy monitors these ward stocks, ensuring timely replenishment and addressing any discrepancies. This hybrid approach balances the efficiency of the unit dose system with the immediate needs of patient care.

Sustainability

A crucial consideration for any large-scale medication system is sustainability. Mr Mustakallio acknowledges the potential for increased plastic waste with unit dose packaging and emphasises the hospital’s commitment to moving towards the more easily recyclable materials, including less plastic and more paper. In fact, Sinteco has now developed plastic-free packaging materials for all unit dose drug management, including compostable plastic clips to hold the unit dose pouches together.

Mr Mustakallio also emphasises that the unit dose system is expected to reduce significantly the amount of waste medication from unused portions of original packs that has to be destroyed (under the existing system). This shift towards reducing overall medical waste is a key environmental benefit.

Project management

The unit dose project at Oulu Hospital is a meticulously planned undertaking managed by the hospital’s in-house project office, involving specialists from various departments, including pharmacy. The selection of Sinteco as the supplier followed a rigorous public healthcare tender process, with their offer deemed the best. The rollout is planned in phases, starting with a pilot involving about 100 patients. Following the pilot, the system will be implemented ward by ward, with a projected completion time of approximately one year.

The success of this ambitious project will be evaluated based on several key metrics relevant to pharmacy and nursing:

- time saved for nursing staff

- decrease in medication process mistakes

- reduction in medical waste

- economic impact on the pharmacy and the hospital as a whole

The positive anticipation from the nursing staff underscores the perceived benefits of this system in streamlining their workflows.

Conclusion

In conclusion, Oulu University Hospital’s implementation of a smart unit dose medicines distribution system represents a significant advance in hospital pharmacy practice. By leveraging sophisticated automation and integrating with hospital-wide systems, this project aims to enhance patient safety, improve nursing and pharmacy efficiency and reduce medical waste. The insights gained from this initiative will provide valuable information to pharmacists and healthcare institutions who are considering similar transformations to their medication management processes. The dedication to sustainability and the systematic approach to implementation further underscore the forward-thinking nature of this project, positioning Oulu University Hospital at the forefront of smart healthcare innovation.

Sinteco robots at Oulu hospital: L to R – Calypso OS (oral solids), Calypso Omnia (all forms) and Pegasus (storage robot). Image courtesy of Wallineva Photography